|

|

RS485 Interface

The cabinets controls and monitoring, as well as, the feeders all communicate with the main computer via a two wire RS485 interface. This is a highly reliable and efficient protocol that saves on wiring in the room.

|

|

|

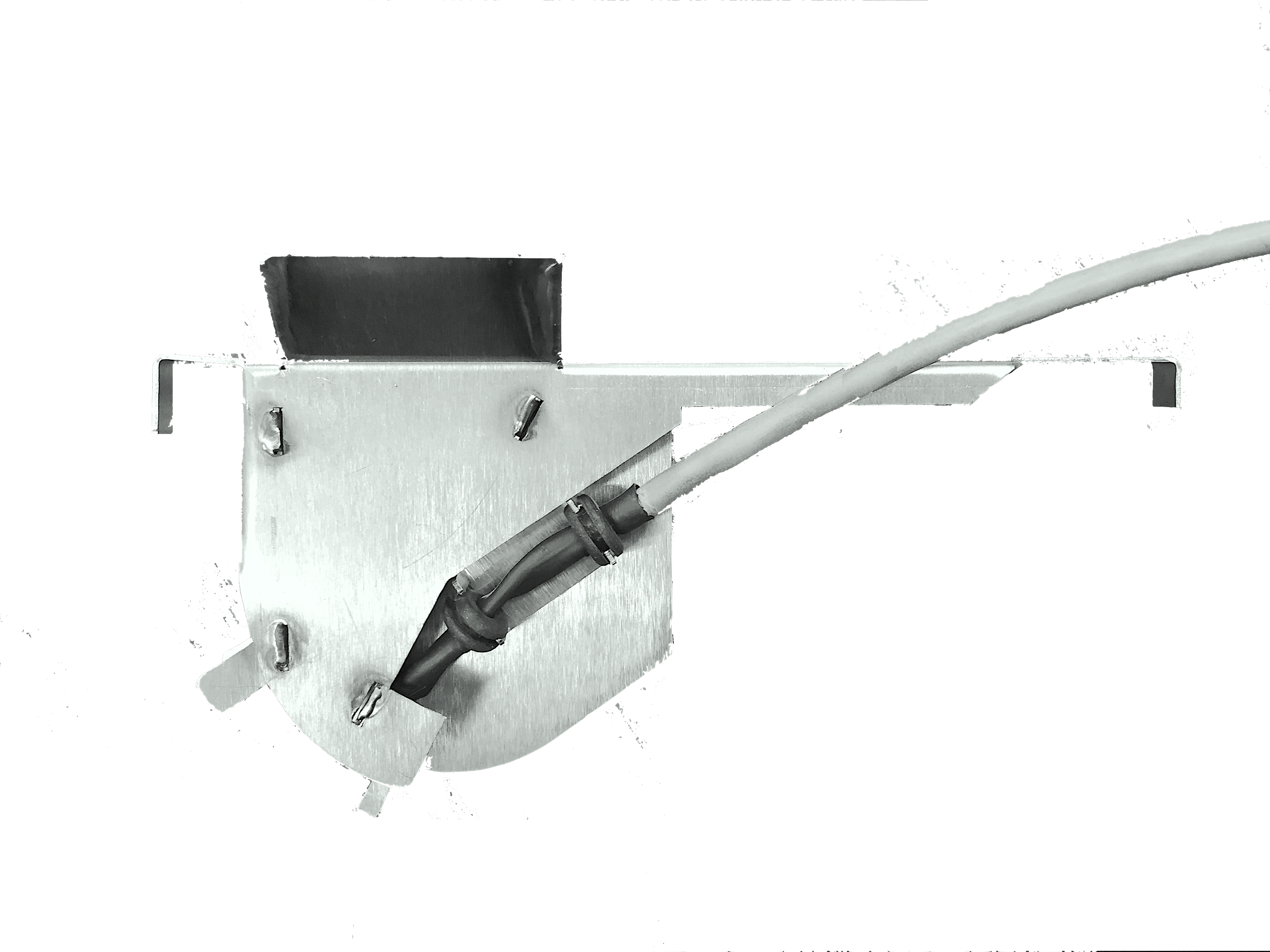

Chute In Lid

With our designs, we have tried to keep things simple and cost effective, therefore we try to build the feeders around a cage with no modifications. As seen here, the chute just fits into the wire lid, and will present the pellet directly in front of the mouse.

|

|

Feeder Loader

Efforts are made to make the feeders easy to load using a loader which conveniently guides the pellets into the feeder hoppers.

|

Automated Feeders

Our feeder design is simple and robust, works well with existing computers, and is cost effective. We use a well known and robust commication standard that minimizes wiring in the room, and configures the network so that minimial interruption occurs within the room.

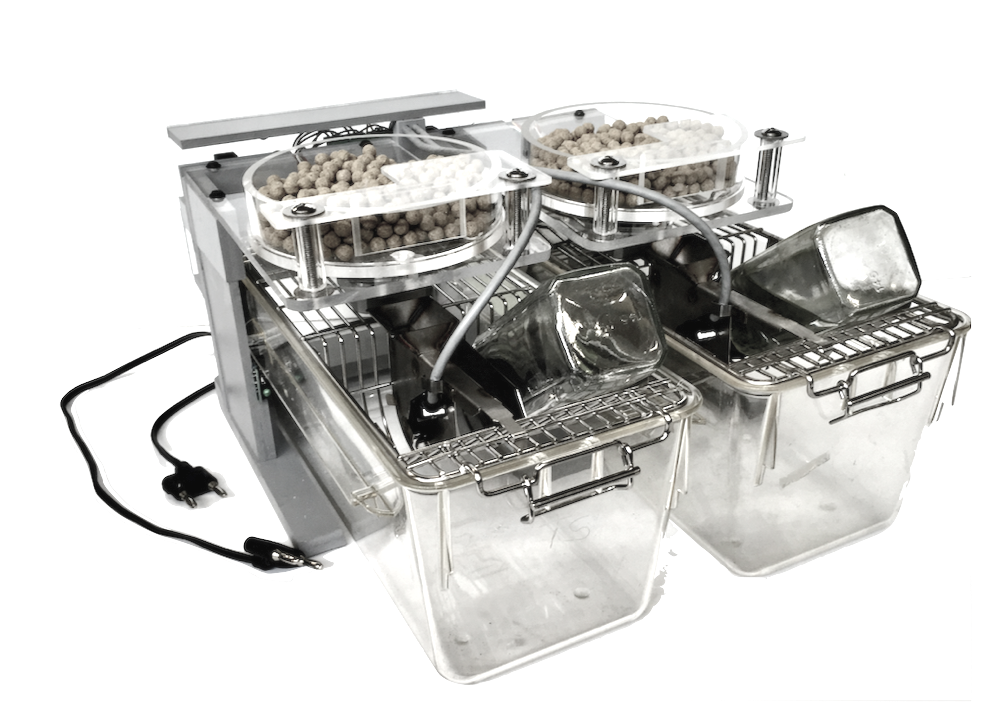

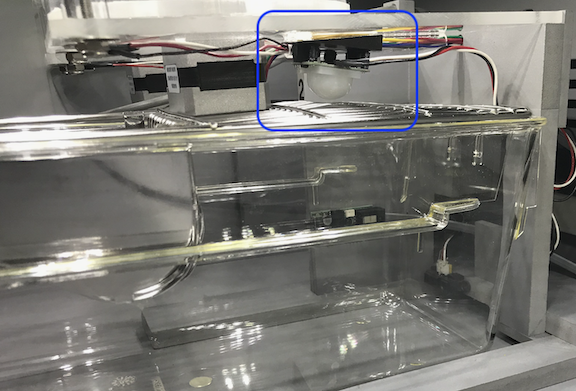

Dual Feeder with Cages

Our standard feeder is a dual design, that is two cages can fit within a single feeder cradle. The pellets are from Bio-Serve and are 300mg size (We are working on different sizing .). We have built feeders for Tecniplast cages 1144B, 1284L, and GMX500.

|

|

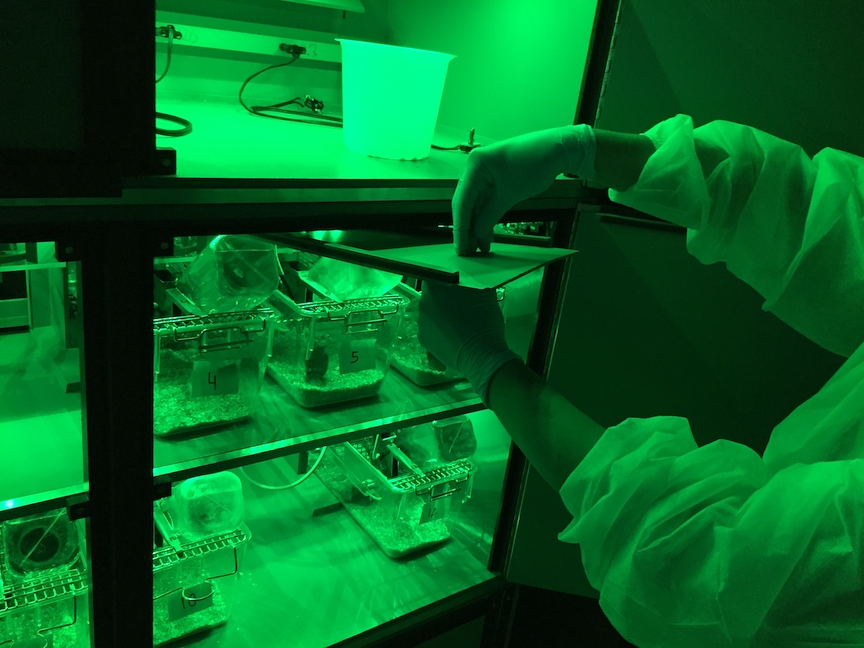

GMX500 Cage with Feeder Feeders can be modified to accomodate various caging. For the GMX500 caging with a filter top, the feeder was modified to drop pellets through a modified lid into the food bin at the back of the cage.

|

Adding Pellets to Feeder The original feeder required a design that used existing cabinetry and caging while keeping costs to a minimum. To overcome some of the limitation, we make a simple loading plate so that the pellets can roll into the hopper.

|

In this screen grab, Actimetrics software is displaying the feeding activity of the mice. Each pellet taken by the mouse is represented on the graph as a single white dot over the timeline. Each line of dots represents a single cage. Click the link for more information.

|

Feeders Ready for Cages

We have designed the feeder to cradle the cage within the cabinet. Cages slide easily into the cradle and the pellets drop into the chute which sits atop the wire lid and holds the pellet in place until the mouse takes it.

|

Requirements for feeder system:

- Standard caging

- Ad-lib feeding schedule

- Easy to swap cages.

- Use existing cabinets

- Minimal cost

- Simple wiring

- Subnet for each cabinet

- Low current draw

Cage Related |

|

|

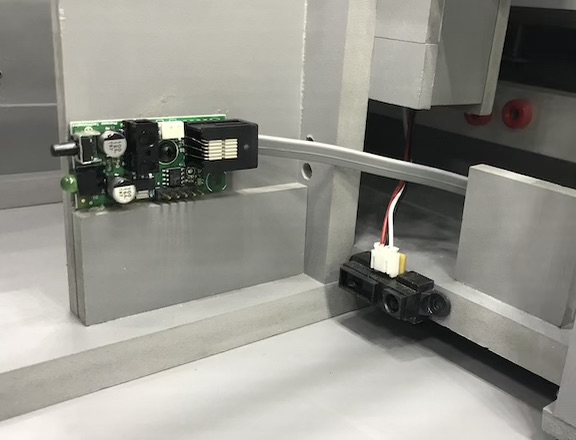

Metal Chute

The metal chute captures each pellet that is dropped from rotating food hopper and holds it directly in front of the sensor at the end of the cable. Once in place the mouse can easily access the pellet through the wire lid of the cage. Once taken Actimtrics Chamber Control Software will record the event.

|

Wheel Sensor

A clickless wheel sensor can be mounted on the cradle of the feeder which will facilitate cage replacement and cleaning by eliminating the cumbersome switch.

|

|

|

PIR Sensor Under Feeder

To assist with with activity monitoring without a wheel. We can provide a PIR sensor mounted to the underside of the feeding plate above the wire lid of the cage.

|